At this year’s ISPE UK Affiliate Annual Event 2025, Neil Wetherall—Global Tulip Operations Director and Managing Director of Factorytalk UK—delivered a powerful session that explored one of the most pressing questions in life sciences manufacturing:

Why is composable MES the right fit for the factory of the future?

Neil’s session delivered practical clarity and a forward-looking vision, showing how manufacturers can accelerate digital transformation with no-code, composable MES platforms. Composable MES is ideal for the factory of the future because it offers faster deployment, effortless adaptability, seamless data integration, and AI-ready scalability—while reducing costs and enabling continuous improvement.

In short, the MES of the future must be agile, integrated, intelligent, and cost-effective.

The Impact: Benefits for Manufacturers

When these characteristics come together, a composable MES can dramatically improve total cost of ownership and operational outcomes:

1️⃣ Faster Development Cycles

Deploy apps and improvements much quicker than traditional MES projects.

2️⃣ Greater Agility

Update workflows and digital processes effortlessly, responding faster to operational change.

3️⃣ Lower Costs

Reduce dependency on external software development—and empower teams internally.

Exploring No-Code MES

What exactly is “No-Code”?

No-code platforms let users build applications without writing any code. Think drag-and-drop, cloud-based, intuitive interfaces. If you’re comfortable with common office software, you can start building.

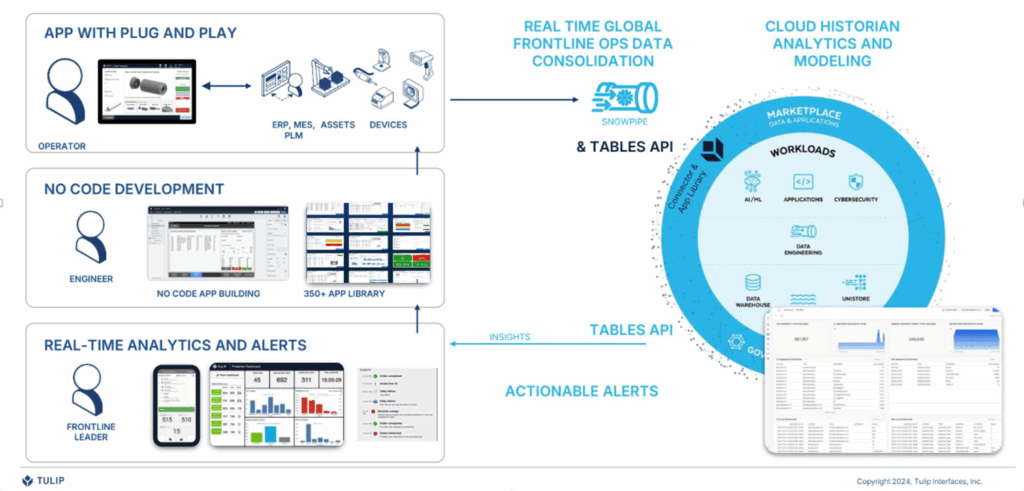

This is the foundation of Tulip, a connected frontline operations platform that enables manufacturers to rapidly build, integrate, and scale shop-floor applications with ease—empowering teams to digitize processes, capture data, and drive continuous improvement without traditional development barriers.

How does Tulip support integration?

The Tulip platform was designed with integration in mind. It supports all modern—and many legacy—integration methods. You can easily connect to ERP, machines, edge devices, and business intelligence tools like Snowflake.

What are the challenges of building MES with no-code?

Like any complex IT project, there are challenges. You’re not starting from a pre-built MES template, so you must define what to include—and what to leave out. If citizen developers are involved, you must ensure alignment with existing IT systems and avoid duplicate solutions across teams. And of course, validation remains essential.

Validating a No-Code MES

Factorytalk uses a standardized solution lifecycle, digitized and executed within the Tulip platform—meaning:

Tulip is used to validate its own applications called Tulip Lifecycle Management (TLM).

This approach ensures compliance while remaining fast, scalable, and flexible.

Governance: The Non-Negotiable

The most important capability is the right governance model.

Citizen developers can be transformative, but only when supported by:

- Defined validation rules

- Clear scope boundaries

- Strong oversight

- Continuous improvement mindset

Final Summary

A no-code, composable cloud MES is a key enabler for the factory of the future.

With it, manufacturers can:

- Build MES capabilities faster

- Adapt processes with flexibility

- Reduce costs through self-service development

- Empower citizen developers to drive digital transformation

- Leverage continuous development as new platform capabilities emerge

But success depends on one thing above all: strong governance.